Thermal performance—the degree of energy transfer between a building and its surroundings—is an important consideration for every construction or renovation project. Not surprisingly, exterior wall assemblies play a major role in achieving the desired performance.

At Patriquin Architects, we’re continually exploring new wall options to meet specific project conditions. Whether or not a client is interested in pursuing formal certification for their building such as LEED or Passive House, we’re committed to promoting excellent environmental performance in the buildings we design.

A robust exterior envelope that is well-insulated, airtight, and employs careful vapor control is essential. However, there are many paths to achieving these goals. Which approach we recommend varies based on specific project conditions, goals, and team members.

Below is information on three different exterior wall assemblies from three projects either recently-completed or current. These examples help illustrate how owners can make their buildings more energy-efficient.

Each building profiled achieves excellent thermal performance through different means. This performance is indicated by a wall’s “R-value,” which is the total “thermal resistance” of a wall. Higher values represent more insulation and walls that are, consequently, less susceptible to energy transfer to or from the exterior.

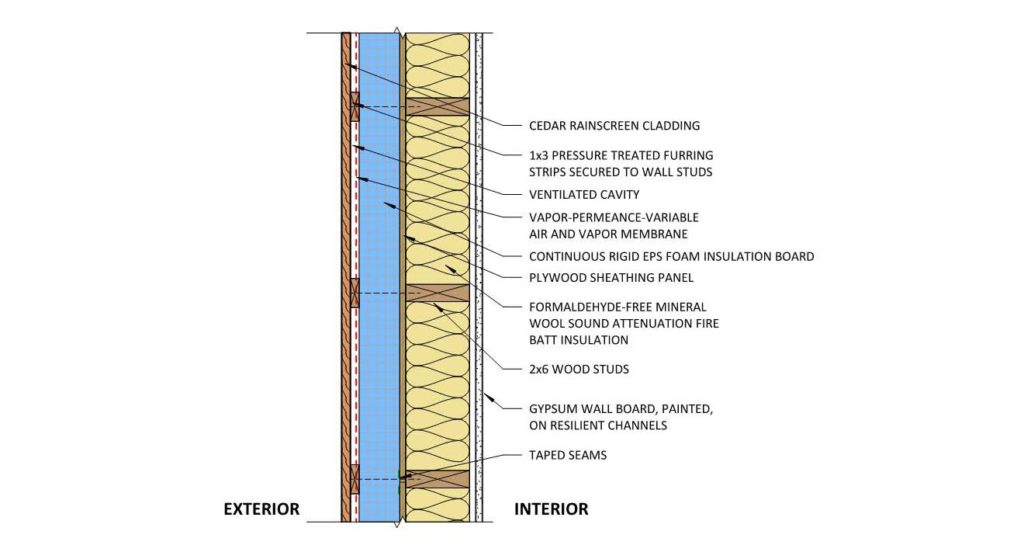

High-Performance School

Wall type: The “Perfect Wall”*

*According to Building Science Corp and the National Research Council of Canada, among others…

- An exterior wood rainscreen provides ventilated cladding, allowing wall components to dry and resist moisture damage

- A vapor-permeance-variable air and vapor membrane manages moisture drive between exterior and interior depending on the season, to keep the wall components dry and interior spaces comfortable

- Continuous exterior rigid EPS foam** insulation minimizes “thermal bridges” from interior to exterior and provides additional insulation

- Continuous NAUF (no-added urea formaldehyde) plywood sheathing with taped seams delivers air and moisture control

- 2×6 wood stud framing with formaldehyde-free mineral wool insulation provides thermal and acoustical protection

Approximately R-40

This relatively common type of wall provides excellent thermal and moisture management in a recently-completed school project while using fairly typical construction strategies, including wood stud framing and widely available types of insulation. It made the most sense for this particular project, where there were very tight time and cost constraints but also a desire to achieve the best envelope possible.

A wintertime challenge demonstrated the excellent performance of this wall assembly, when a mechanical compressor failed and one of the buildings lost heat for several days in a row during a January week with temperatures in the teens. Despite the cold weather outside, the interior temperature never dropped below 62 degrees (and in fact, passively increased throughout most days as the winter sun was allowed to warm the building through large south-facing windows), meaning people could continue to use the building comfortably. This demonstrates the way in which excellent wall assemblies ensure not only energy-efficiency, but also resiliency through volatile weather events.

**EPS (expanded polystyrene insulation) works better than other types of foam in this case because it does not off-gas and its production does not require harmful blowing agents such as CFCs (chlorofluorocarbons), HCFCs (hydrochlorofluorocarbons) or HFCs (hydrofluorocarbons).

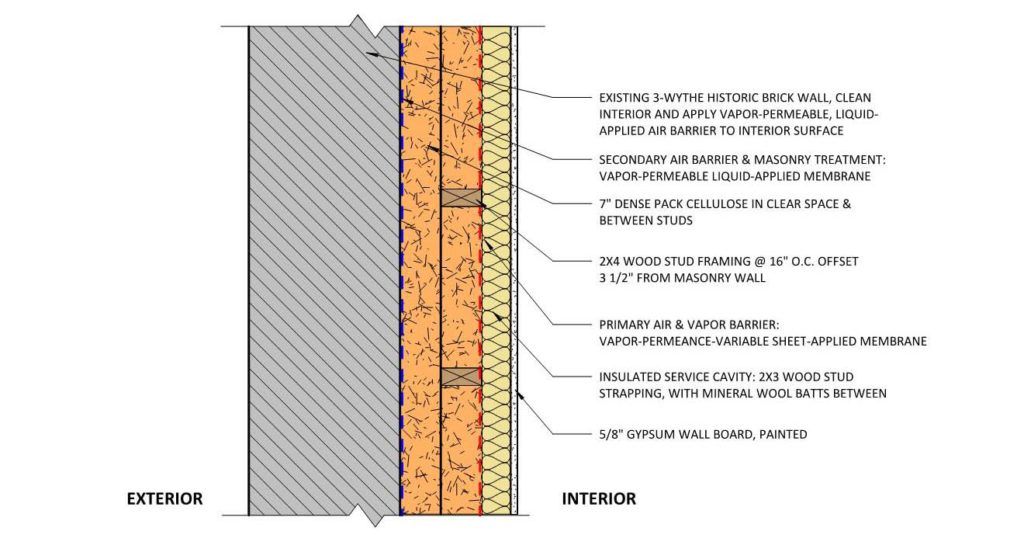

King’s Block Passive House Retrofit

Wall type: New “interior” exterior wall (inside the existing brick wall)

- Existing brick walls provide the main barrier against exterior water, and have been coated with a new liquid-applied air barrier on the interior to provide a first layer of protection from air and vapor movement

- New 2×4 wood framing with 7” of blown-in dense-pack cellulose insulation provides excellent thermal protection

- A vapor-variable air and vapor barrier membrane manages moisture drive between exterior and interior depending on the season, to keep the wall components dry and interior spaces comfortable

- New 2×3 wood-framed service cavity with mineral wool insulation provides space for routing electrical and plumbing lines without penetrating the air and vapor barrier, and also functions as additional insulation

Approximately R-38

As part of our office’s Passive House renovation, we are building an entirely new “exterior” wall assembly on the interior of the existing historic brick walls. The existing brick walls provide very little thermal performance themselves, but are to remain untouched on the exterior because of their historical significance to the neighborhood.

Instead, we are constructing 7” of new wall on the interior, including dense-pack cellulose insulation and two advanced air and vapor barriers. In addition, a 2.5” “service cavity” inside the main air barrier will allow for changing uses of the commercial spaces over time—including rerouting of power and data lines—without having to worry about puncturing the critical air barrier.

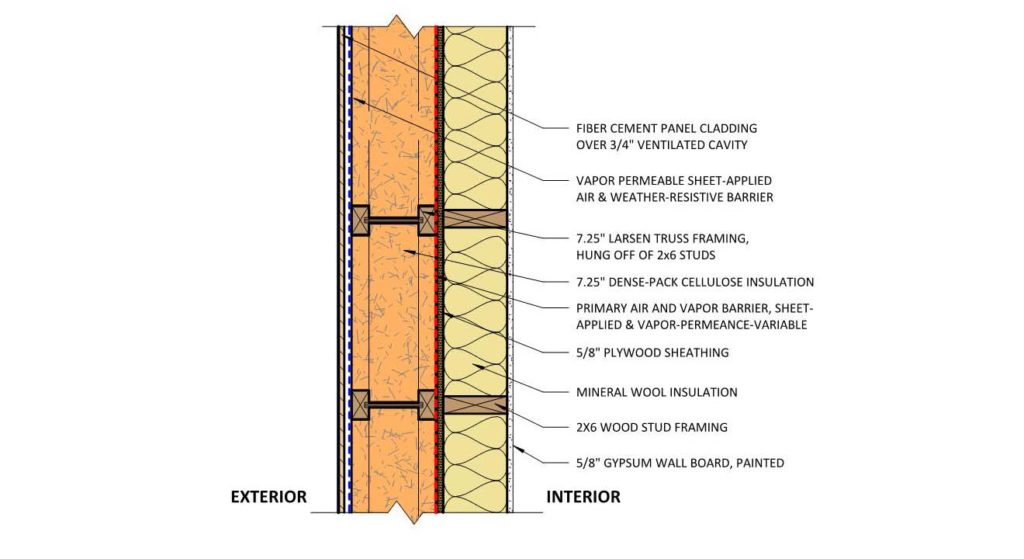

Connecticut Passive House

Wall type: Larsen Truss wall

- Fiber cement rainscreen cladding helps keep the wall ventilated and protects against moisture damage

- 7.25”-deep Larsen Trusses with blown-in dense-pack cellulose provide the majority of the wall’s insulation

- A vapor-variable air and vapor barrier membrane manages moisture drive between exterior and interior depending on the season, to keep the wall components dry and interior spaces comfortable

- 2×6 wood-framing with mineral wool insulation provides structure, space to route electrical and plumbing, and a first level of insulation

Approximately R-47

For this residential new construction project, we are working with a builder who is experienced with Passive House and high-performance design. He recommended that we use the strategy of a “Larsen Truss” wall, in which a heavily insulated exterior wall assembly is hung off of standard wood stud framing. This allows for more insulation and excellent air sealing, and minimizes thermal bridges.

An Open-Minded Approach to Exterior Detailing

As with all detailing considerations, the exterior wall assembly we specify for any given project is highly dependent on the specific conditions. New construction offers very different opportunities than an existing building retrofit, for example.

By keeping an open mind and being willing to consider alternate techniques recommended by builders or other collaborators, we are able to land on the specific solution that delivers the best thermal and moisture management to meet a particular project’s needs.

If you have questions about exterior wall assemblies, or simply want to learn more about our firm and the services we offer, please contact us at your convenience.